How to Install Electrical Wiring

Use these tips and instructions for adding new electrical wiring. Take a few minutes to read the directions thoroughly. Following these instructions can save you time and effort and ensure a safe installation.

BASIC PRINCIPLES OF GOOD WIRING

Before beginning any electrical repair, shut off the power. Remove the fuse or trip the breaker for the circuit you will be working on in your service panel. Use a neon tester to be sure the power is off. If there is any doubt, you can remove the main fuse or trip the main breaker. Remember: Removing the main fuse or tripping the main breaker will usually shut off the power to the entire house.

Electrical wires are color coded to prevent wiring errors. White wires almost always connect to other white wires or to chrome terminal screws on switches and receptacles. Some wiring devices–such as receptacles–are back-wired by pushing the bare wire end into spring grip holes. These wiring devices are plainly labeled to show which color goes into each spring grip hole. Switches are nearly always connected into black wires in cables. The only exception is where a cable is extended, making it necessary for the white wire to play the role of the black wire. When this is necessary, the white wires should be painted black to prevent future wiring errors. Study the wiring diagram. This will help you understand the basic principles of good wiring. Also, find a good electrical how-to book. It's one book every homeowner should keep on hand for ready reference. Most home wiring is complete with either No. 14 gauge or No. 12 gauge wiring. No. 14 is the smallest wiring permitted under most codes. Always use the same size cable for a continuation of any extended wiring circuit.

CONNECT NEW WIRING TO LAST OUTLET IN CABLE

New wiring should be connected to the last outlet in a run of cable. To locate the last outlet in the run, shut off the current. Remove the cover plates from each outlet on the circuit. The last outlet in the run has wires connected to only two of the four terminal screws. The two unused terminal screws on the last receptacle serve as a starting point for wiring to a new outlet.

ATTACHING CABLE FOR NEW WIRING

Shut off the power to the circuit you will be working on at the service panel. Loosen the screws holding the receptacle in the box and remove it, as shown. Attach the the earth wire (the bare or green) to the chrome terminal. The yellow (or green in some instances) wire should be connected to the receptacle and the box maintaining the equipotential bonding on the earth system. The earth wires should only be connected to the correct screw terminals on the recepticle to the brass terminal on the receptacle and to the box, if the box is metal. Use care to match the size of the original cable. If No. 12 wire is used, continue with No. 12. If No. 14 wire is used, use No. 14 for continuing the cable. The size of the cable is usually stamped on the side of the cable. New wiring can be connected to continue the run beyond the last receptacle. Note that the new wires are pulled through knockout plugs in the back of the outlet box.

ADDING NEW WIRING FROM A JUNCTION BOX

New wiring can also be tied into a junction box, unless the wiring in the junction box is already at maximum capacity. Before tying in at a junction box, always trace the cables leading to the box to check the voltage. Be sure you are not connecting a 120-volt outlet to a run of wire providing 240 volts for larger appliances. To tie in new wiring at a junction box, first shut off the current at the service panel. Locate the main supply cable coming into the junction box from the service panel. Locate the supply wire by tracing the white wires. All white wires in the junction box will be attached to the white wire on the supply line. Knock out the unused plug on the junction box and run the new line from the box as illustrated. Be sure to use a cable clamp to secure the cable to the junction box.

TYING IN NEW WIRING AT A CEILING LIGHT

You can tie in new wiring at a ceiling light if the light is not controlled by a switch. Shut off the current at the service panel. Tie white wires to white wires and black wires to black wires, as illustrated. Connect the ground wires as illustrated. If you are using a metal box, attach them to the box as well as the light fixture. Knock out an opening in the outlet box, and continue the new wiring as illustrated.

ALWAYS MATCH CONNECTORS TO TYPE OF CABLE USED

Some boxes come with built-in connectors. Armored cable connectors have inner rims to hold fiber bushings at the end of the cable. Nonmetallic cable connectors are designed to grip the installation around the cable with a two-screw clamp. Regardless of the type of cable used, always leave about 6" to 8" of wiring in the box to allow plenty of wire for making easy connections. You can tighten the nut on either type of cable connector by placing a screwdriver in the notch and tapping the screwdriver lightly.

MAKE ALL CONNECTIONS IN APPROVED BOXES

Always remember that connections must be made in an approved box. Never connect one cable to another by an open-line splice. All switch, outlet, and junction boxes must be positioned so they are always accessible. You can easily remove knockout plugs with a nail punch, screwdriver or metal rod.

RUNNING NEW CABLE BETWEEN MULTIPLE FLOORS

Drill a hole through the floor from bottom to top, as illustrated. Be sure the hole is drilled into the recessed area behind the wall rather than in the open. Be sure to use a bit that's large enough to permit free passage of the wiring cable.

Run the cable through the newly drilled hole to the desired location for the new receptacle or switch. Bring the cable through the opening by using a weight on the end of a string and a wire with a hook on the end.

Using this same technique, you can add one outlet to another by drilling up through the floor, pulling the cable under the floor, and then running it to the desired position on the opposite wall. The same wiring can be pulled through for either receptacles or switches.

ADDING NEW WIRING FROM BOXES IN CEILING

If your home has an unfinished attic, it may be easier to add new wiring by attaching it to boxes in the ceiling. In this way, gravity works for you rather than against you. Attach the cable to the box as previously described.

Cut a hole in the wall at the desired location for the switch or receptacle, and run the cable from the box in the ceiling to the new outlet location. Bring the new cable through the wall and ceiling by cutting and drilling holes in and through the wall, the 2x4 plate, and the ceiling. A special fish tape is available for these types of jobs.

ADDING NEW WIRING ON THE SAME WALL

You can connect new cable from an existing outlet to a new outlet on the same wall by running it inside the wall. Mark the approximate location of the new outlet. Using a stud finder locate and mark the wall studs. Start one stud before the existing outlet and end one stud after the new outlet. Mark the exact location of the new box. Make it the same height as the existing box. Do not locate it over a stud. Using a drywall or keyhole saw, cut the opening for the new box. Using a utility knife and a drywall saw, cut a strip of drywall about 3" wide out of the wall, below the outlets. Start at the center of the first stud you marked and end at the center of the last stud; watch for nails as you cut. Carefully remove the drywall strip. Using a hand or circular saw, make two cuts 1" apart and 3/4" deep in each of the exposed studs. Using ahammer and a chisel, remove the wood between the two saw cuts.

Be sure the power is off to the existing outlet. Remove the cover plate and the receptacle. Remove one of the knockouts in the bottom of the box. Run the new wire behind the wall and up through the knockout in the box. Tighten the clamp and attach the wires. If the box does not have a clamp, place a wire clamp on the new cable. Tighten the screw to hold the clamp on the wire. Be sure the nut is off the wire clamp and run the wire up to the box as before. Feed the threaded end of the clamp up through the knockout, replace the nut and tighten. Replace the receptacle and the cover plate. On the new box, remove one of the knockouts in the bottom of the box. If the box you are using is a self-clamping box, insert the box into the wall and tighten. If not, insert the box into the wall, insert a Madison hanger on each side of the box, and bend the tabs over into the box to tighten. Finish running the wire from the existing box through the notches and up behind the wall into the box as before. Clamp the wire and install the receptacle as in the figure. Install the cover plate, turn on the power, and test the circuit with a neon tester. Shut off the power again to safely finish the project. Nail metal cable protectors to the exposed studs over the notches. Replace the drywall strip you removed earlier. Use the spackling compound and drywall tape to complete the installation. Cable can be pulled from an existing box on one wall to a new outlet on the opposite side of the same wall.

Attach a cable to the existing receptacle in the box as previously described. Allow ample slack in the cable to permit easy connection to the new box to be installed on the opposite wall. Bring the cable through the new opening with a wire, as illustrated in. Connect the cable to the new box, attach the desired receptacle, and mount the box to the wall with box supports if it is not near a stud.

TOOL AND MATERIAL CHECKLIST

- Two-Wire Cable

- Switches

- Screwdriver

- Extra-Long Bit

- Conduit

- Fish Tape

- Outlet Boxes

- Electrical Tape

- 1/4" Drill

- Cable Connectors

- Pigtails

- Hand or Circular Saw

- Madison Hangers

- Drywall Tape

- Cable Protector Plates

- Switch Boxes

- Side Cutter Pliers

- Wire-nuts

- Chisel

- Drywall or Keyhole Saw

- Three-Wire Cable

- Receptacles

- Brace

- Ripping Bar

- Wire

- Neon Tester

- Stud Finder

- Hammer

- Spackling Compound

--

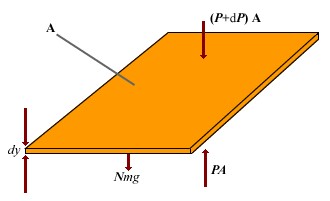

, where I is the total steady current passing through any surface bounded by closed path

, where I is the total steady current passing through any surface bounded by closed path

is the rate of change of temperature of an object with respect to time t.

is the rate of change of temperature of an object with respect to time t. is the ambient temperature and K is the experimental constant

is the ambient temperature and K is the experimental constant

,

,  is obtained as follow

is obtained as follow

,

,